LK-HG-3 Automatic hot-melt spraying machine

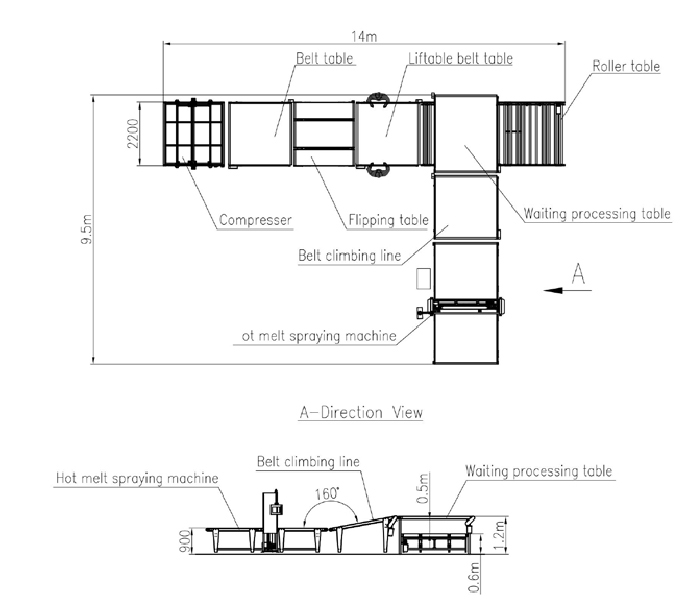

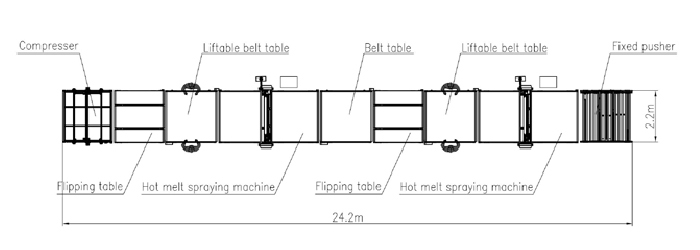

Drawing

| AdvantagesMechanical description and characteristics |

|

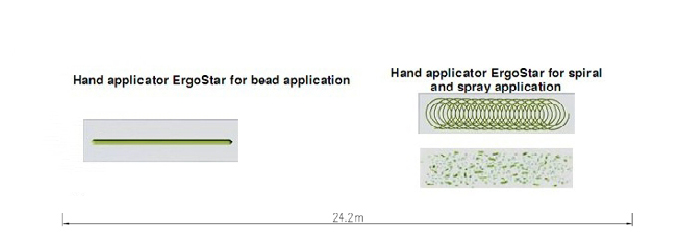

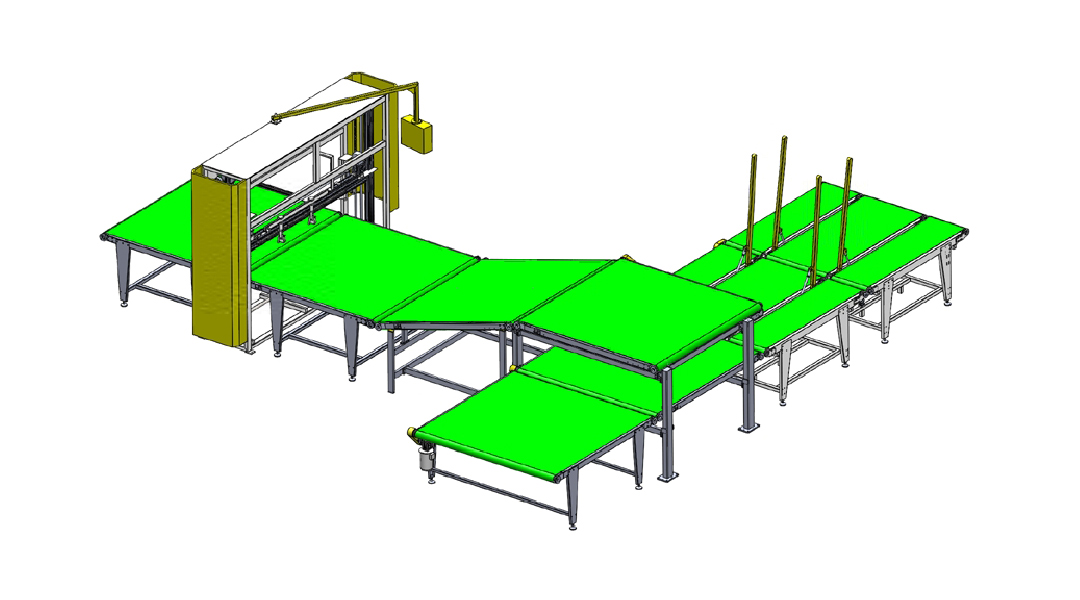

Designed to create foam encased units and/or adhere quilted mattress panels.Features a hot melt adhesive with either a spin-spray or bead application.Gluing heads oscillate left and right while

applying adhesive and provide controllable application of adhesives,adjustable speed gluing application,and silicone laminated conveyor or belts with cleaning rollers,without manually adjusting and

positioning. 1. PLC control system,can be connected mattress production line; 2. Advance Switzerland Robatech Brand adhesive melter; 3. Conveyor belt guides ensure accurate tracking; 4. Ergonomic design and operator friendly; 5.Low loss,low cost |

| Specifications |

|

||||||||||||||||||||